Pervaporation

Pervaporation

What is Pervaporation (PV) process?

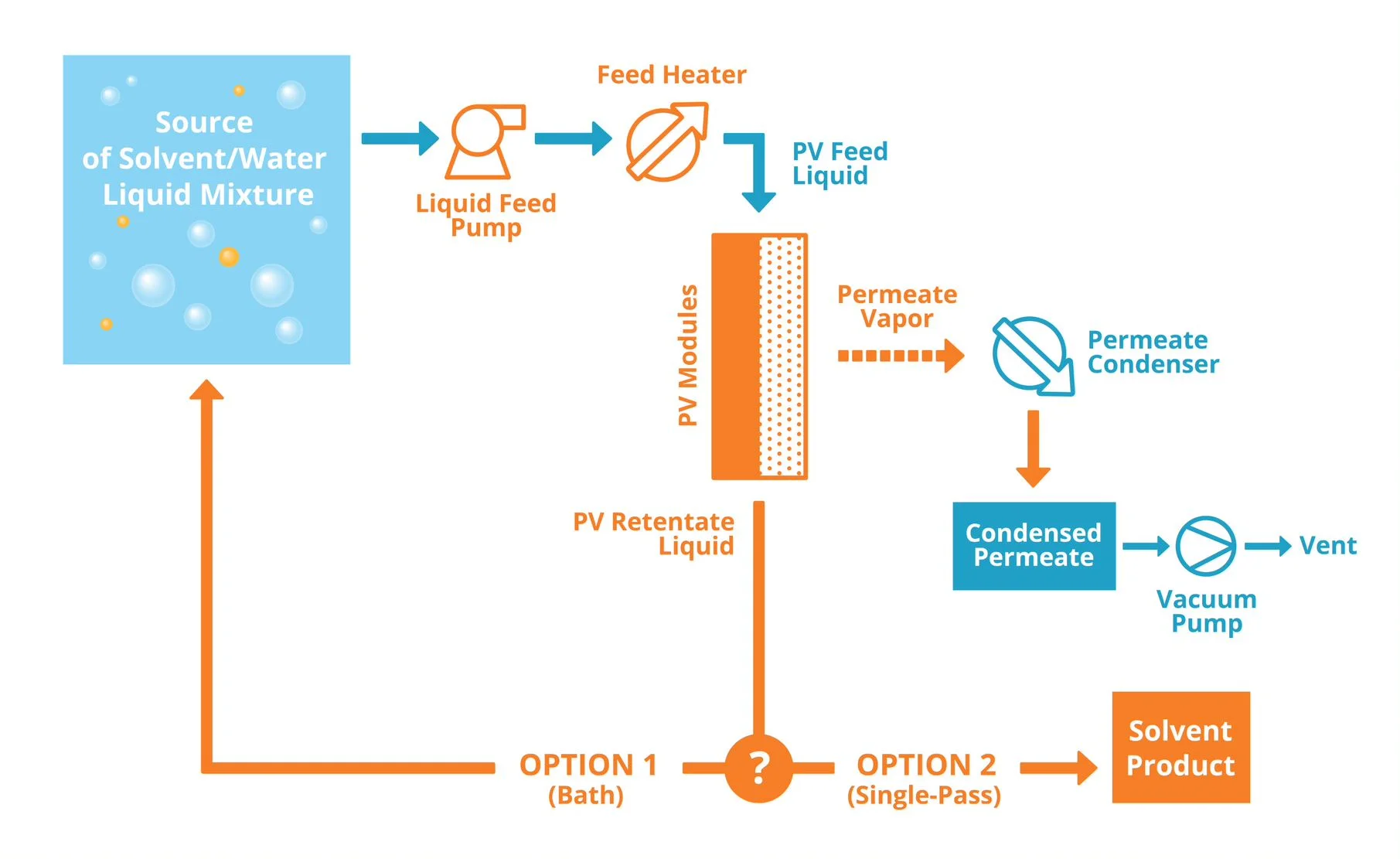

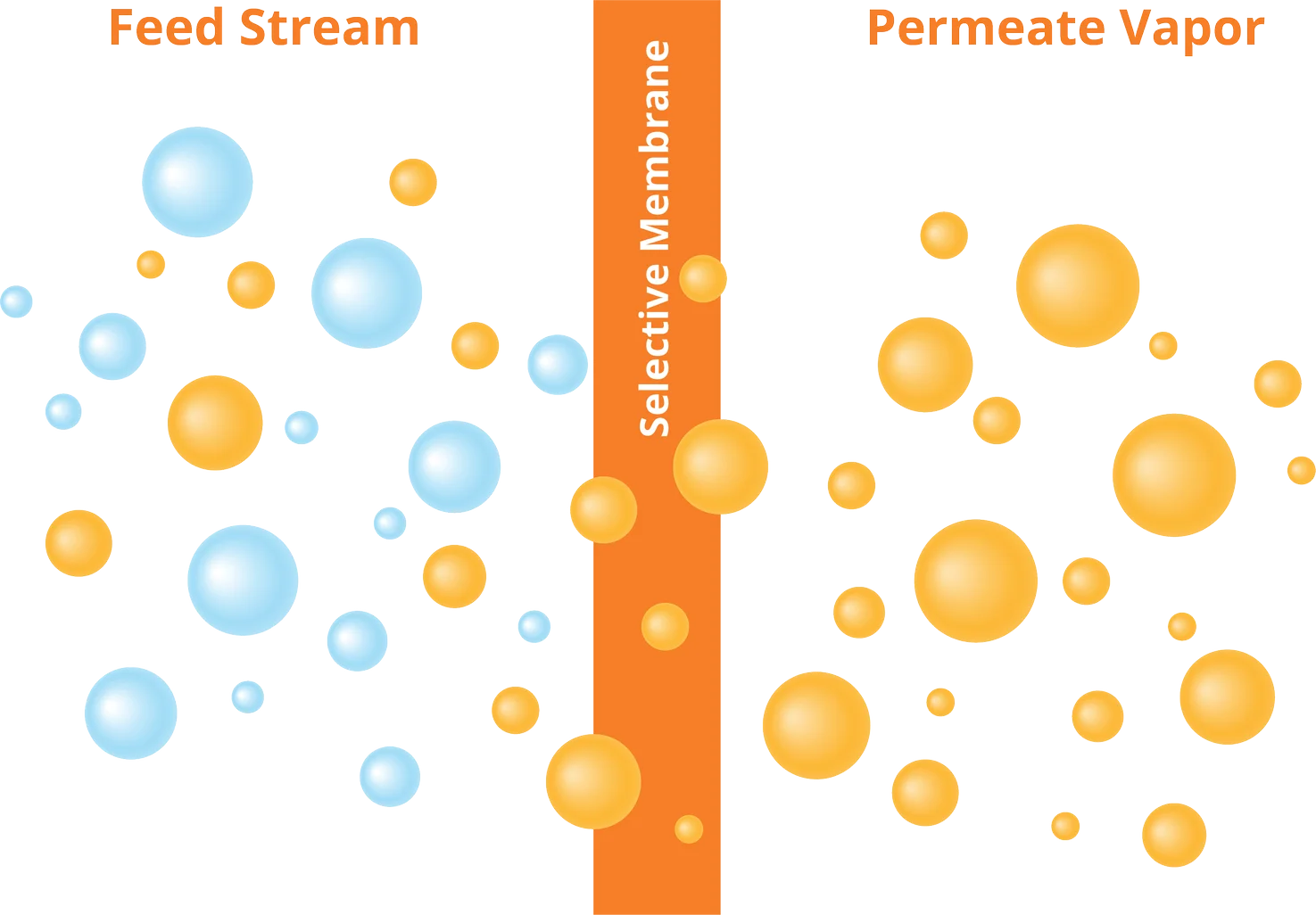

Pervaporation (PV) is a separation process that consist of two phenomena: permeation and evaporation.

PV Membranes are able to separate certain components that are low in concentration from its fluid mixtures.

How Pervaporation Works?

Pervaporation (PV) is a separation process that consist of two phenomena: permeation and evaporation.

PV Membranes are able to separate certain components that are low in concentration from its fluid mixtures.

What are the applications of Pervaporation Membranes?

Solvents Dehydration

PV Membrane System dehydrates azeotropic solvent mixtures and separates pure solvents at high purity and far beyond the azeotropic point.

AZEO-SEP® is PV hydrophilic non-porous membrane suits solvent dehydration applications and available in sheets or hollow fiber.

Solvents Recovery

PV Membranes System recovers solvents, volatile organic compounds /VOCs, from aqueous streams before it is disposed in the waste effluent drainage.

VOC-SEP® is PV hydrophobic non-porous membrane suits solvents recovery applications and available in sheets or hollow fiber.

Are there other alternative technologies?

Distillation:

-

- Conventional Distillation Column (Cannot break azeotropes).

- Extractive Distillation Columns (Multistage columns and uses entrainer).

- Pressure Swing Distillation Columns (Multistage columns at different pressures).

- Limitation

- High energy consumption

- High Capital Cost

- Large footprint

Adsorption:

- Molecular Sieves.

- Limitation

- Feed process stream shall be in superheated vapor form

- Needs multiple beds for continuous operation

- High energy consumption during regeneration process

- Large footprint

Learn more about how pervaporation works

“Learn more and download the PDF.”

Pervaporation

Send download link to:

Turnkey solutions

that will save you money and help the planet.